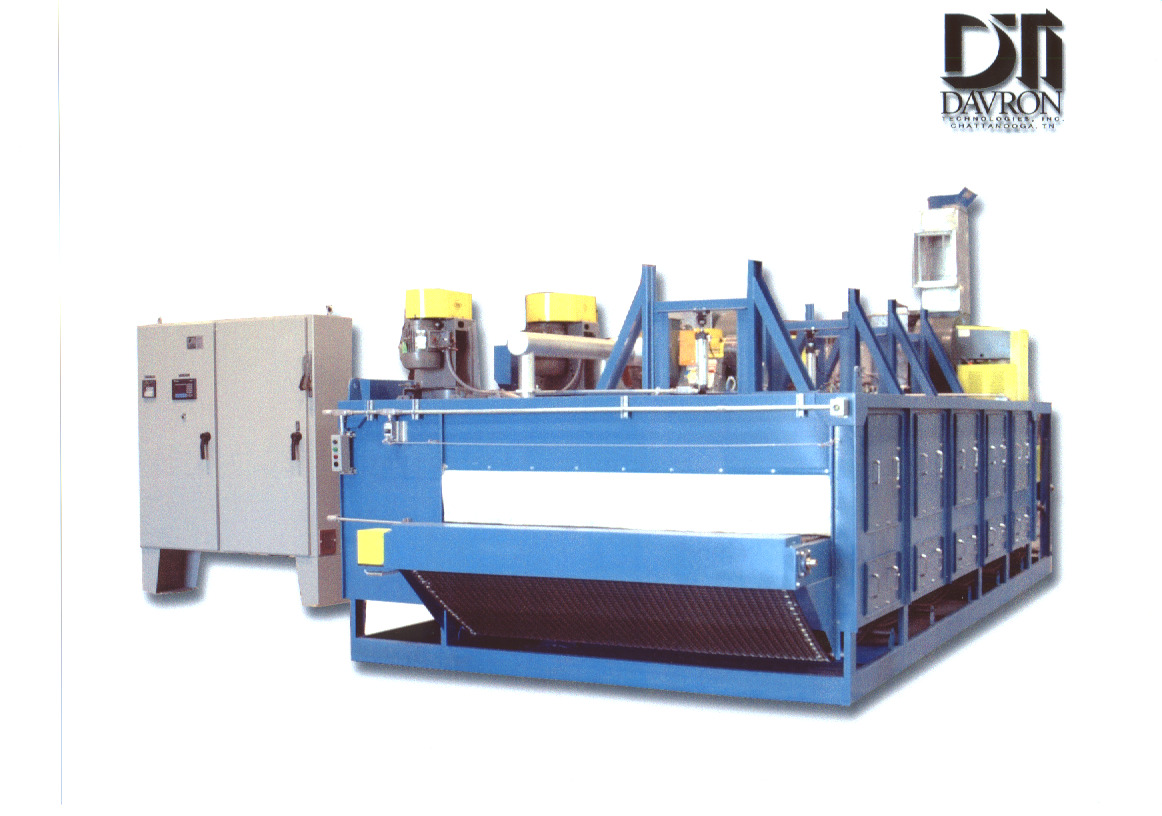

DTI-762 Indexing Conveyor Oven

Description

The DTI-762 curing conveyor type oven cures automotive disc brake pads. This system is designed to work in conjunction with manual presses. Parts are press formed and placed in four baskets across the width of the conveyor belt. Based on index time, the conveyor oven indexes a row of baskets through the cure chamber.

Specifications

| Chamber External Dimensions | 22′-0″ L x 10′-11″ W x 5′-7″ H (6706mm x 3327mm x 1702mm) |

| Conveyor Usable Size | 21′-4″ L x 7′-8″ W x 1′-6″ H (6502mm x 6604mm x 457mm) |

| Insulation Thickness | 6″ (152mm) |

| Conveyor Extensions | 2′-0″ (610mm) Entrance End, 1′-0″ (305mm) exit end |

| Conveyor Type | Flat Wire Belt |

| Conveyor Control | PLC controlled index motion based on distance and time |

| Heat Source | Four SCR controlled electric heaters |

| Design Operating Temperature | 200°F – 500°F (93°C – 260°C) |

| Maximum Operating Temperature | 500°F (260°C) |

| Operating Voltage | 480-volt / 3-phase / 60-hertz |

| Control | PLC control of all functions |

Alternative capabilities

Davron Technologies, Inc. provides process specific industrial inert atmosphere oven applications, including the following:

- Industries Served: Automotive, Pharmaceutical / Medical, Aerospace, Glass, Composites

- Materials/Parts Processed: Castings, Glass, Plastics, Steel, Engine Components, Cast Steel/Aluminum

- Process Applications: Inert Stress Relieving, Inert Atmosphere Annealing, Inert Atmosphere Batch, Inert Atmosphere Conveyor/Continuous