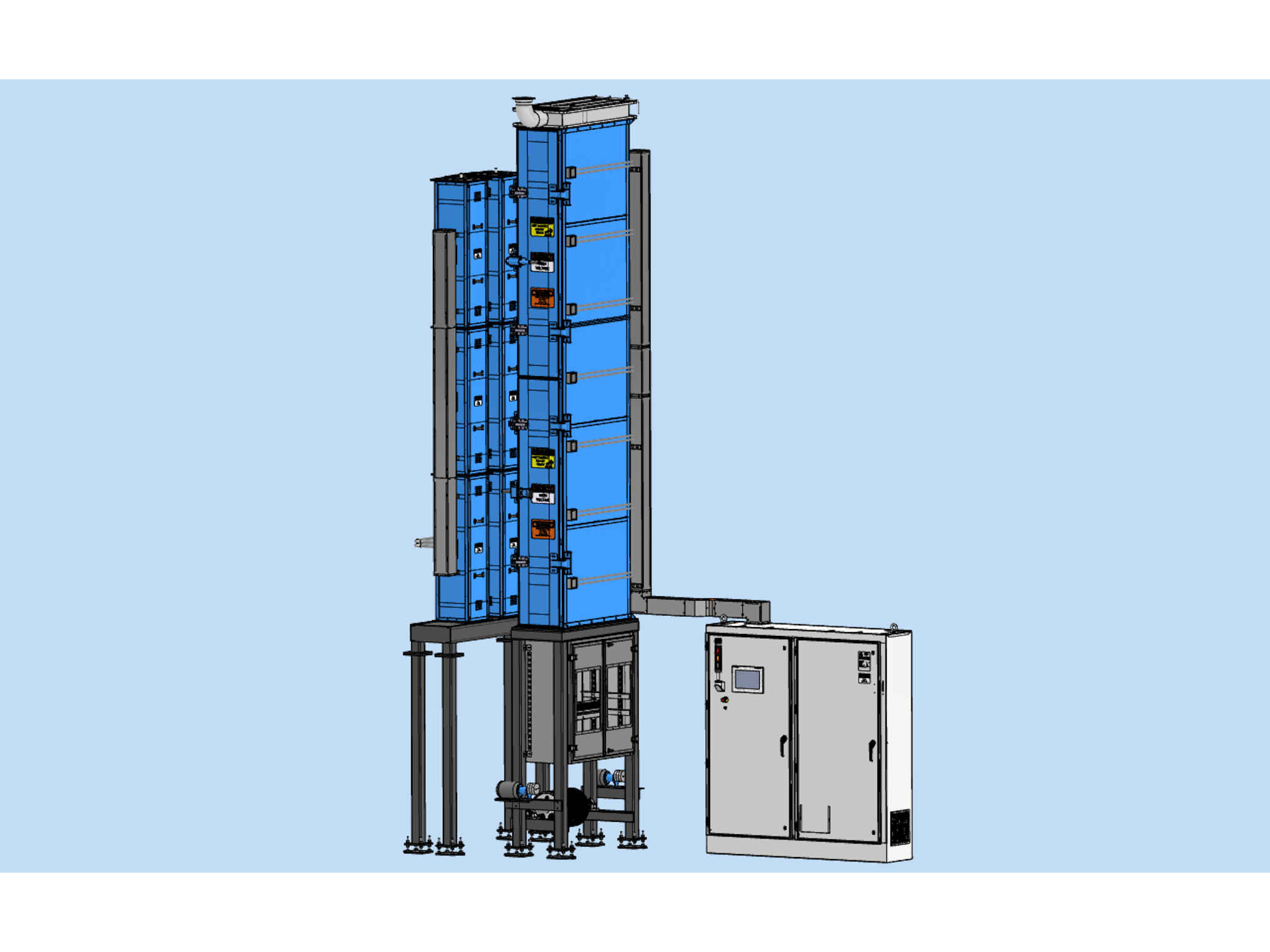

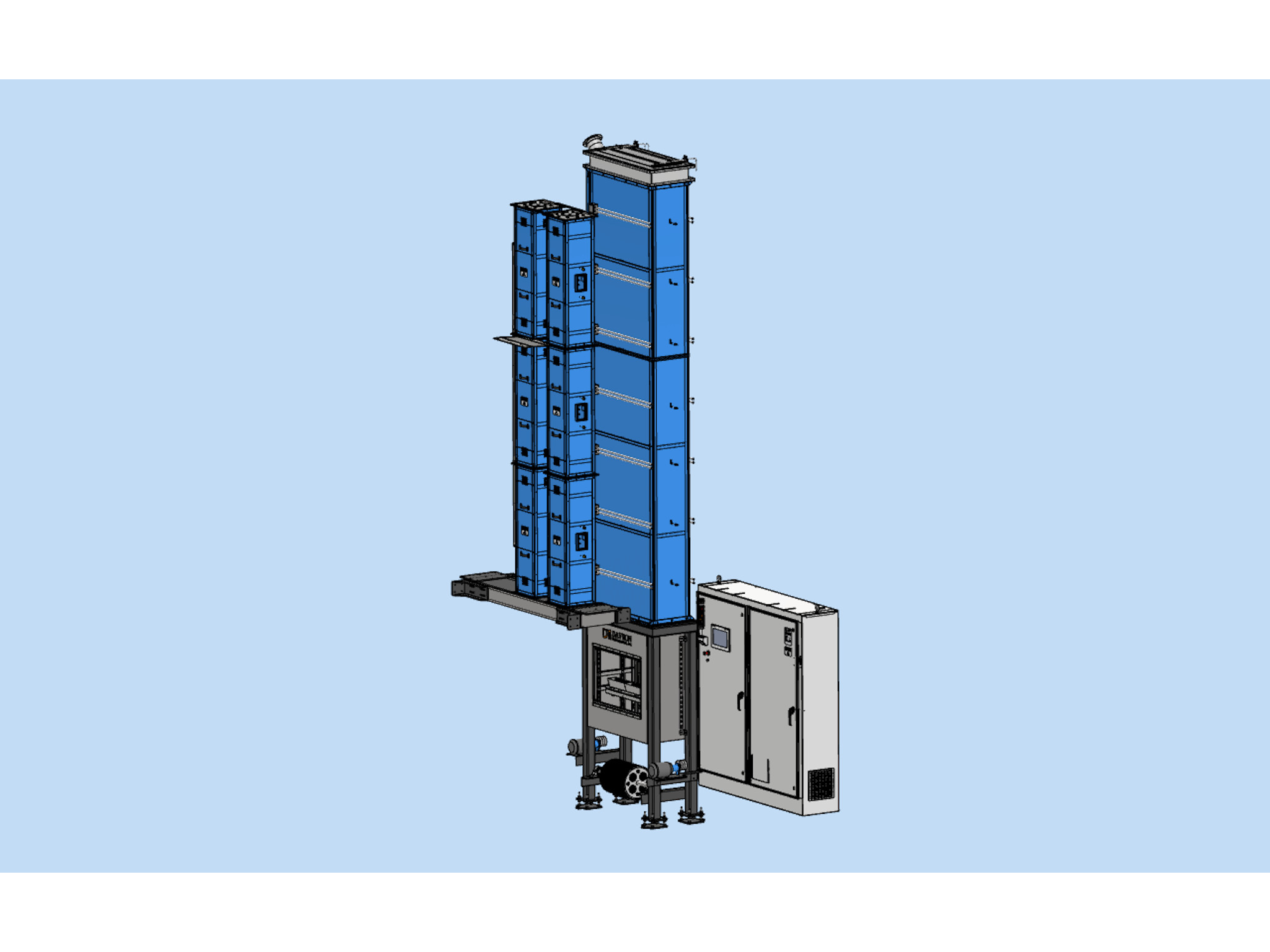

DTI-1455 Wire Enameling Vertical Oven

Customer directive

DTI-1455 Vertical Curing Oven provides manufacturing capability for the Medical and Pharmaceutical Industry in a vertical arrangement to save valuable manufacturing floor space. DTI-1455 includes multiple zones of temperature control to match the requirements of the product being processed, as well as maintain accurate temperature control and uniformity. Heating elements within the oven are located on both sides of the vertically oriented product flow to provide even heat distribution.

Description

The DTI-1455 Vertical Oven System includes one (1) vertical oven, two (2) annealing systems, and one (1) catalyst system. The first stage of the process is product traveling vertically through the oven to cure the product coating. The oven provides baffles top and bottom of the oven to minimize airflow and keep heat inside the oven. After traveling through the oven, the product is then traversed through the annealing systems. Both the oven and the annealing systems include multiple zones of heat to ensure the required temperature is reached to cure and anneal the product. The heated catalyst system is included to remove any volatile byproducts of the process.

Specifications

| Product Being Processed | Medical Grade Tubing |

| Oven Dimensions | 1′-10″ L x 4′-5″ W x 15′-5″ H (559mm x 1346mm x 4699mm) |

| Heated Chamber Dimensions | 0′-2″ L x 3′-0″ W x 14′-4″ H (51mm x 914mm x 4369mm) |

| Type of Heating System | Electric IR Heaters |

| Oven Design Operating Temperature | 275°F – 875°F (135°C – 468°C) |

| Oven Maximum Operating Temperature | 1000°F (538°C) |

| Product Support | Supply and return pulleys below and above the heated chamber. |

| Controls | PLC/HMI control system |

Alternative capabilities

Davron Technologies, Inc. designs and manufactures ovens of this type to meet many unique process requirements, including but not limited to, the following:

- Airflow: Designs can be completed to provide airflow from any direction within the heated chamber as required by the product. This particular process no airflow but it can be added if need be.

- Industries Served: Manufacturing/Regeneration, or any industry that requires batch processing.

- Materials Processed: Medical grade rubber.

- Other Processes: Preheating, Curing, Drying, Solvent Drying, Bonding

- Heating Systems: Modulating Gas Fired Direct or Indirect, Electric, or Thermal Oil.